R&D

Research and development is driven by a plain concept: the tool must adapt to the constraints of the project, and not to the project to the limits of the tool!

The cornerstone of this axiom is the modular system, constantly enriched and developed by the evolution of the industrial and construction methods. XL engineers see in each and every opportunity a mean of pushing forward the state-of-the-art.

Inventions and processes developed lead to many patents, from which the most strategic are internationally recorded. Protecting ideas gives XL the ability to constantly invest in research and development.

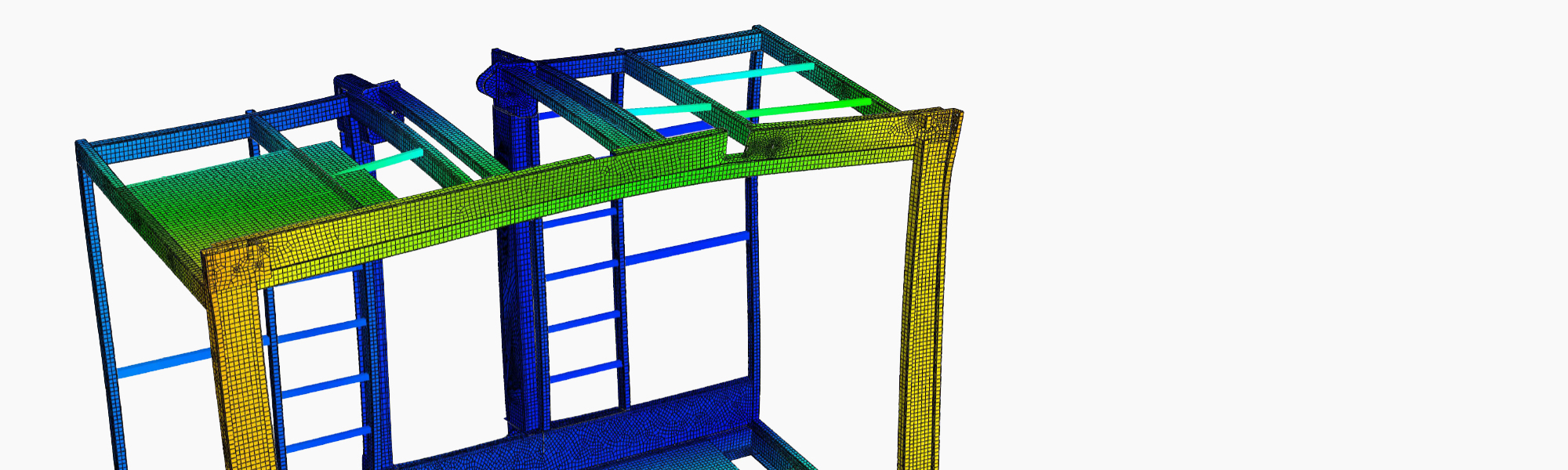

XL designers and engineers imagine, create, and develop solutions to improve the state-of-the-art, general performance and safety of the equipment.